|

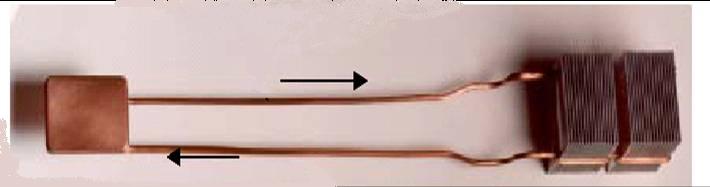

(LHP) are an attractive alternative for heat regulation of electronic equipment, fuel cells thermal management. The channels for vapor and liquid flow are separated. Flexible lines makes possible to dispose evaporator and condenser at a large distance from each other and at different orientation.

The performance of the evaporator depends on the transport properties of the wick, i.е. permeability, thermal conductivity as well as structural characteristics of the wick. In the LHP there is a possibility to use an evaporator above the condenser, the vapour flows through the vapour channels towards the condenser and the liquid goes back the evaporator due to the capillary pressure head of the porous wick.

LHP are widely distributed comparing with loop thermosyphons (LTS) due to its insincerity to the gravity field.

Developed LHP has optimal heat flow rate equal to 800 W (maximum is near 1500 W) at the working temperature near 80 °C. The thermal resistance of the evaporator is 0.06 К/W. LHP flat evaporator is made from copper with sintered powder porous structure.

|