| 1. The way to increase the efficiency of hydrocarbons storage, transport and transformation.

The considerable potential impact on the energy systems and nature protection can be realized by wide application of fuel cells and solid/liquid sorption transformers, consuming hydrocarbons as a fuel. Combination of fuel cells and solid sorption transformers with heat pipe thermal control is a good basement for energy tri-generation. For example the heat rejected by exhaust gases of reformer/fuel cell system, or natural gas internal combustion engine is a good energy resource for solid sorption heat transformers to recover this energy.

The goal of the research Program is to suggest, design and develop new systems of hydrogen storage and transport (fuel cartridges) and to increase the fuel cells efficiency , using heat pipes (thermal management) and solid sorption machines for wasted heat recovery:

1. New light sectional fuel cartridges with sorbent composites and heat pipe thermal management for fuel (hydrogen, natural gas and hydrogen reach gases) storage at low pressure. Fuel cartridges (to store the natural gas, or hydrogen) for fuel cells is convenient to design as low pressure vessels. The sorbent material is applied as the high sorbtion capacity sponge to store the fuel.

2. Solid sorption machines for fuel cells heat recovery, air-conditioning and space heating/cooling. Solid sorption heat pumps and coolers are good candidates to transform the waste energy of fuel cells and to cool electronic devices. Recently sorption machines are suggested to be applied in a small-scale combined cold, heat and power systems for transport.

3. Heat pipes for fuel cells thermal management. At least two types of heat pipe coolers are interesting to consider. The first one is the heat pipe spreader to equalize the temperature field inside the fuel cell stack. The second one ensures the waste heat dissipation in the surrounding. Besides this main category of heat pipe application in fuel cells thermal control there are possibilities to apply heat pipes in ancillary systems as fuel cartridges thermal control and systems for fuel cells heat recovery (co-generation and tri-generation). Heat pipes are responsible for the heat redistribution between the fuel cell, fuel cartridge and heat pump. Heat pipes for fuel cell thermal management ought to have high effective thermal conductivity and be insensitive to the gravity forces. The vacant porous media for such mini heat pipes is the metal sintered powder wick or the silicon/carbon porous wafer with bi-porous (micro/macro pores) composition, saturated with working fluid. Heat pipes are capable to perform precise thermal management of fuel cells and increase its efficiency.

4. The multistage adsorption systems and fuel cells are linked together by heat pipe heat exchangers and thus the heat and mass recovery from one stage system to another is performed. All above mentioned devices are temperature sensible and need to ensure its thermal control. Solid sorption machines with complex compound sorbent material (active carbon fibre and micro/nano chemical particles on its surface) are the subject of the research in the frames of this program.

2. Heat Pipe thermal management for the Renewable and Non Conventional Energy Sources

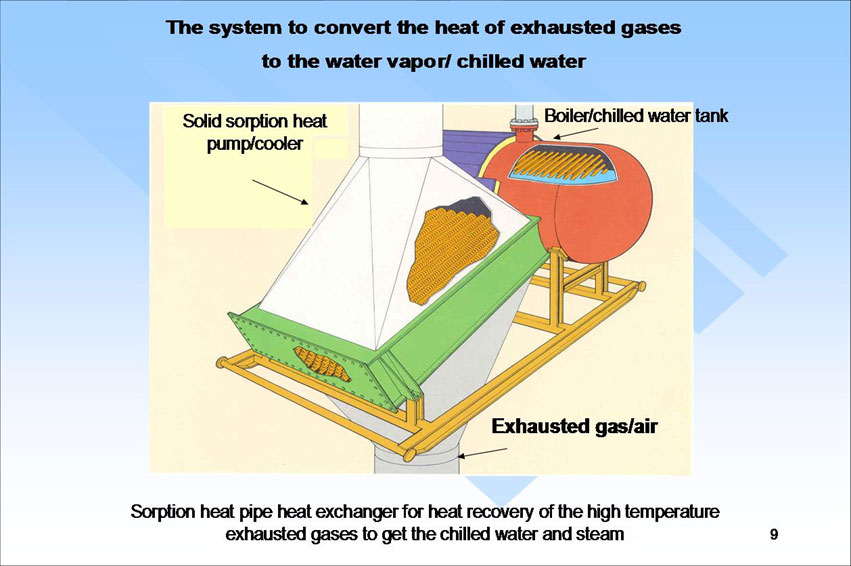

Heat pipes are a good tool to perform the adsorption machines thermal management and increase its efficiency. The increasing utilization of energy at low heat source temperature is a key issue for both industry and academia. In recent years, the heat-activated adsorption cycles are proven to be practical and energy efficient method for converting low-temperature waste heat into useful effects such as cooling, freezing, heating, storage and desalination and this is reflected by the dearth of literature publications. The adsorption technology would steer towards the key development of heat activated machines for the energy industry and they could offer cost-effective solutions for achieving energy efficiency and environment sustainability. Heat pipes are convenient and efficient devices to organize the thermal management of modern Renevable and Non-conventional Energy sources. They are easily integrated into the multistage adsorption systems and ensure the heat and mass recovery from one stage system to another. Sorption heat pipes can be considered as the typical component of sorption heat pumps and refrigerators, Fig. 1 –Fig.2.

Fig. 1 Sorption heat pipe as the component of the heat pump/chiller

Fig. 2 Sorption heat pipe heat exchanger

Heat pumps can be composed with tens, or hundreds of such units. Recently heat pumps are encompassed on the application in a small-scale combined cold, heat and power system, which utilizes the motor waste heat, fuel cells or PVT panels for cold production (tri-generation system).The solid sorption heat pumps and coolers with complex compound sorbent material (active carbon fibre and micro/nano chemical particles on the surface of the fibre) are considered together with heat pipe thermal control system. Such sorption machines are very compact, light and have a good potential to be used in the solar energy recovery, air-conditioning, heating/cooling, fuel cells, electronic thermal control and transport applications. New types of solid sorption machines (heat pumps, coolers, transformers) were designed and tested with heat pipe thermal control for wasted heat recovery (rejected by the post-combustion exhausted gases of a reformer/fuel cell system).

|